How to Maximize Storage Efficiency With Bulk Plastic Containers

Wiki Article

Making The Most Of Space and Lowering Waste: The Benefits of Using Mass Containers in Different Industries

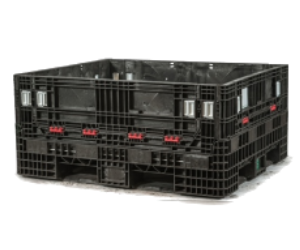

Making use of mass containers has become significantly common across sectors. Their capability to take full advantage of storage space and decrease waste offers significant benefits. These containers improve procedures, minimize packaging demands, and improve supply chain performance. As organizations goal for sustainability, the adoption of bulk services is becoming a tactical selection - Plastic Bulk Containers. What continues to be to be explored are the certain advantages and study that illustrate their effect on numerous industriesThe Adaptability of Mass Containers in Different Sectors

Bulk containers play a crucial function throughout various markets, showing remarkable adaptability in their applications. In farming, they facilitate the storage and transport of plant foods and grains, optimizing area and making certain item integrity. The food and beverage market depends on mass containers for the reliable handling of ingredients like sugar, flour, and liquids, decreasing contamination dangers. In the chemical field, these containers securely store and transport unsafe products, adhering to strict security regulations. Furthermore, the building and construction sector take advantage of mass containers used to keep aggregates and other materials, boosting website organization. Their versatility includes recycling and waste administration, where mass containers streamline the collection and handling of recyclable products, highlighting their important function in varied functional contexts.

Enhancing Supply Chain Efficiency With Bulk Solutions

When companies integrate bulk services right into their supply chains, they often experience considerable enhancements in performance and cost-effectiveness. Mass containers simplify storage space and transportation procedures, enabling greater volumes of goods to be managed concurrently. This decrease in taking care of time minimizes labor costs and minimizes the risk of damage during transit. Furthermore, bulk solutions can optimize inventory administration by minimizing the regularity of orders, which brings about decrease purchase prices and boosted capital. Boosted presence of supply chain information sustains much better decision-making and permits prompt changes based upon need variations. Organizations can accomplish greater agility and responsiveness, inevitably positioning themselves for competitive benefit in swiftly altering markets.Ecological Benefits of Embracing Mass Containers

The fostering of bulk containers presents companies with substantial environmental advantages - Bulk Plastic Containers. By decreasing product packaging waste, these containers decrease the quantity of product sent out to landfills, therefore minimizing the overall ecological footprint. Their multiple-use nature not only preserves resources entailed in producing single-use packaging yet likewise lowers energy consumption connected with manufacturing and transport. In addition, mass containers frequently facilitate a lot more efficient logistics, causing less trips needed for delivery and as a result decreasing greenhouse gas discharges. Using bulk containers can likewise advertise sustainable methods within industries by motivating the change in the direction of eco-friendly materials. On the whole, their integration sustains a circular economic climate, contributing to source preservation and advertising a healthier atmosphereExpense Financial Savings and Waste Reduction Through Mass Storage

Organizations can accomplish significant expense financial savings and waste reduction by carrying out bulk storage options. By making use of bulk containers, business can lower product packaging expenses and lessen the regularity of deliveries, causing reduced transport expenditures. This reduction in packaging not only leads to monetary savings however likewise lowers the quantity of waste created, advertising an extra lasting functional design. Furthermore, mass storage enables far better supply administration, lowering perishing and ensuring that products are made use of properly prior to expiry. The structured processes connected with bulk storage can improve efficiency, permitting companies to designate resources better. On the whole, adopting bulk storage space practices adds to a considerable decline in both functional expenses and environmental influence, straightening financial and environmental objectives.Situation Researches: Success Stories From Numerous Industries

Success stories from various sectors highlight the transformative effect of bulk container use on functional performance and sustainability. In the food market, a leading grain provider took on bulk containers, lowering packaging waste by 40% while enhancing storage space capacity. A chemical maker carried out bulk containers, resulting in a 30% decrease in transportation expenses and a considerable reduction in spill incidents. The auto field additionally benefitted; a components maker structured its supply chain with bulk storage, leading to a 25% renovation in inventory turn over. These instance research studies show that companies can attain significant cost financial savings, reduce ecological influence, and improve total efficiency by incorporating bulk Shop Bulk Plastic Containers containers right into their procedures, showcasing a shift in the direction of more lasting practices throughout diverse markets.

Frequently Asked Inquiries

What Materials Are Commonly Saved in Bulk Containers?

Common materials saved wholesale containers consist of grains, liquids, chemicals, accumulations, and different food. These containers are created for performance, permitting easy transport and storage of substantial amounts throughout various sectors.How Do Mass Containers Influence Supply Administration?

Mass containers simplify stock administration by boosting organization, lowering the regularity of restocking, and boosting visibility of stock levels. This effectiveness minimizes mistakes, maximizes storage space, and helps with much more precise forecasting and replenishment processes.Are Bulk Containers Customizable for Details Products?

Yes, bulk containers can be very customizable to fit certain items - Reusable Bulk Plastic Containers. Various materials, dimensions, and designs are readily available, allowing organizations to tailor containers for perfect storage space, transport, and preservation of their one-of-a-kind items and requirements

What Are the Safety Regulations for Using Bulk Containers?

Safety and security policies for utilizing bulk containers vary by industry and region, usually including guidelines for material compatibility, structural integrity, labeling, and dealing with procedures to guarantee safe storage space and transport of non-hazardous and unsafe products.Exactly how Do I Tidy and Maintain Bulk Containers Effectively?

To cleanse and keep bulk containers efficiently, one should make use of ideal cleansing representatives, guarantee thorough rinsing, evaluate for damages, and keep them in a completely dry, orderly environment to prevent contamination and extend their life-span.Furthermore, the building and construction market benefits from mass containers utilized to store aggregates and various other materials, enhancing website organization. Mass containers streamline storage and transport procedures, allowing for greater volumes of items to be handled concurrently. The use of mass containers can also advertise sustainable practices within markets by encouraging the change in the direction of environmentally friendly materials. By utilizing bulk containers, companies can minimize product packaging expenses and decrease the regularity of shipments, leading to lower transportation expenditures. In the food industry, a leading grain distributor adopted bulk containers, minimizing packaging waste by 40% while raising storage capacity.

Report this wiki page